Distance measurement by Laser

This kind of equipment allow to check distances,

thicknesses and geometry of parts during

manufacture process.

|

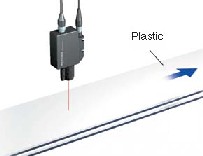

Many parts cannot be palpated mechanically because they are too flexible, too punts or too notched. One can then call upon the optical sensors using the technique of triangulation per laser. The ray emitted by the laser comes to strike the part and generates a luminous task there. An optics, tilted under a determined angle, limited to eliminate the possible disturbances related to diffraction specific to the part, then focuses an image of the zone informed on a sensor consisted photosensitive elements. The laser sensor must be chosen according to nature of material, distance compared to the targeted part and rate of control to be carried out. |

| New multifunction acquisition PCI cards offer performances of very high quality at a very reduced cost. These cards have in general 16 or 32 simple analogical entries (8 or 16 differentials) and a converter A/D 16 bits or 32 bits being able to sample up to 200 Khz. The sampling rate is programmable, via a meter-timer available on the card. It's also possible to directly control sampling by an external clock. The acquisition card, used to sample signals coming from the laser sensor, must be selected according to the speed of the part to measure, the awaited measuring accuracy and the frequency of control to be carried out. |  |

|

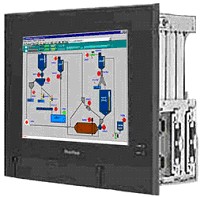

Industrial PC has for principal task the visualization and the control of essential information of production and diagnoses of the process. It has a important archiving capacity and a compatibility with standard office applications. It is reinforced through hard disks assembled on silent block, screen and mother card accepting uninterrupted shocks and vibrations. It can accept industrial CEM and 24h on 24 operating during 365 days. Industrial PC makes possible to treat and display, in real time, measurements of the laser sensor (distances, thicknesses and geometry of part). It can also send signals toward tool machine in order to modify the course of manufactoring process. |

| Workers desk is designed to stand hard industrial environments, without ventilation, without hard disk, with compactness, with fast starting and having degrees of IP65 protection, being able to resist all types of chemical aggressions. It has operating system owner, whose evolution is related to the manufacturer who sells it. Nevertheless, the programmable logic controller of the tool machine can be configured to stop or not manufactoring process according to information sent by the industrial PC which is connected to him. |  |

|

Process is thus completely under control. The least incident of manufacture automatically puts tool machine in safety. In the same way, the process can be stopped as soon as the desired characteristics of part are reached. This kind of control contributes to improve quality and its follow-up but it isn't really effective without a quality system. |

![]()