Thermal Spray

Thermal spraying allow realising many various

coatings onto a broad range of materials

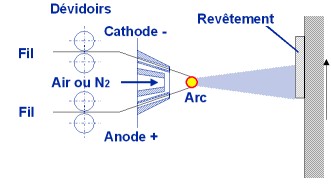

| Consumables are two metallic wires, bulky or tubular. They are guided in the middle of a gas jet (air or nitrogen). An electrical arc occurred between the two wires, melted metal is atomised and thrown on surface of the part to coat. |  |

|

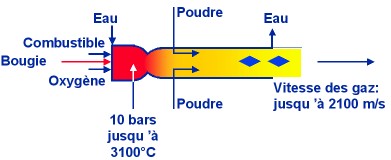

Fuel and oxygen are blended inside the combustion chamber. Combustion, stable and uniform, provokes a constant pressure. Shape and sizes of the ejection pipe allow realising a supersonic gas jet and low pressure area for radial powder introduction. Exit speed of particles is directly in relation with the pressure inside combustion chamber. Melted powder is atomised and thrown on surface of the part to coat. |

| Theses kinds of equipments allow obtaining high performances coatings against wear, corrosion, adhesion or heat. Application domains are various like aeronautics, building, petrochemical, electronics, printing or biomedical. |  |

![]()